Behind the Dirt: South Lawrence Trafficway Expansion Update

When it comes to infrastructure, what’s beneath the surface matters just as much as what’s visible. At BHC, our construction inspection services are the unseen force driving the success of every bridge, roadway, and structural element we help build. We’re not just checking boxes. We’re safeguarding communities, optimizing performance, and ensuring that every detail meets the highest standards.

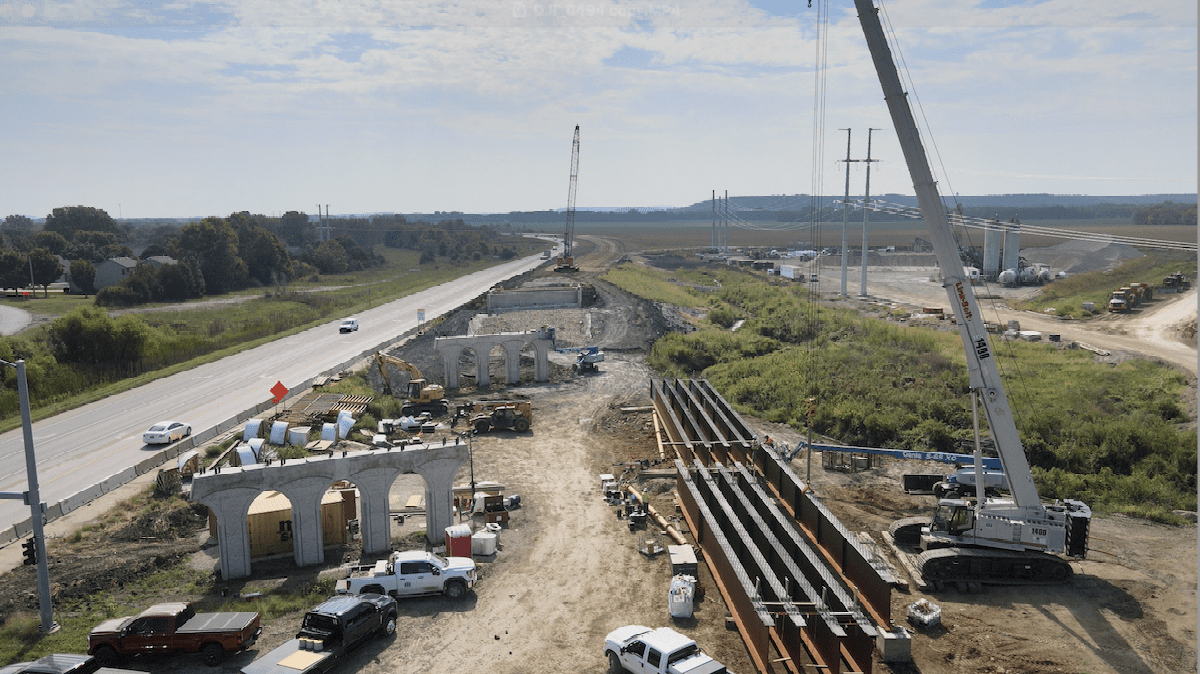

From soil stabilization and steel girder assembly to traffic flow and safety monitoring, our inspection team is involved at every stage of construction. Our expertise ensures that projects are not only built to spec but built to last. In this blog, we’re taking you behind the scenes of our work on the South Lawrence Trafficway expansion to show how BHC’s inspectors help make quality infrastructure possible with ‘No Problem’.

From Dirt to Durable Pavement

What you see behind the scenes is a carefully engineered process. It starts with building a dirt sub-grade, compacted layer by layer using bulldozers and rollers. While it may feel solid underfoot, clay-rich soil has a plasticity that must be treated before it can support concrete pavement.

To stabilize the soil, lime kiln dust (LKD) is applied. This material chemically alters the clay, stripping away the negative charge that keeps particles suspended in water. The result? A firmer, more crumbly soil that can be graded precisely and built upon with confidence.

Once the LKD has done its job, a cement-treated base (CTB) is introduced. This intermediary layer distributes the weight of the concrete pavement evenly across the sub-grade, preventing deformation in weaker areas.

CTB also acts as a moisture barrier, preventing capillary rise, which is the upward movement of water from the sub-grade that could otherwise degrade the concrete over time.

Final Steps: Concrete and Community Impact

With the sub-grade stabilized and the CTB in place, the final layer is complete with concrete pavement. This is the surface that thousands of drivers will use daily. It’s the result of collaboration among hundreds of professionals, from earthwork crews to our construction inspectors, all working together to deliver a safe, efficient roadway.

By next summer, drivers can expect major changes, including new lanes and improved signal timing. These upgrades will help reduce traffic stacking and make travel smoother and safer.

‘No Problem’ is Here to Help

Our inspection team is meticulous, prioritizing thorough documentation, accurate pay estimates, and precise field testing. This approach ensures that nothing is overlooked and that every project we touch reflects our commitment to excellence. Our construction inspectors are ready to help ensure your next project is built to the highest standards. Connect with our team at ibhc.com to learn more.