Roads Done Right: US-50 Highway Construction Inspection

US-50 might look like a quiet rural highway, but it plays a big role in regional transit, especially for trucks, traffic, and travelers heading west toward Colorado. That level of traffic accelerates wear and tear on the pavement, which means projects like this one aren’t just routine maintenance, they’re essential.

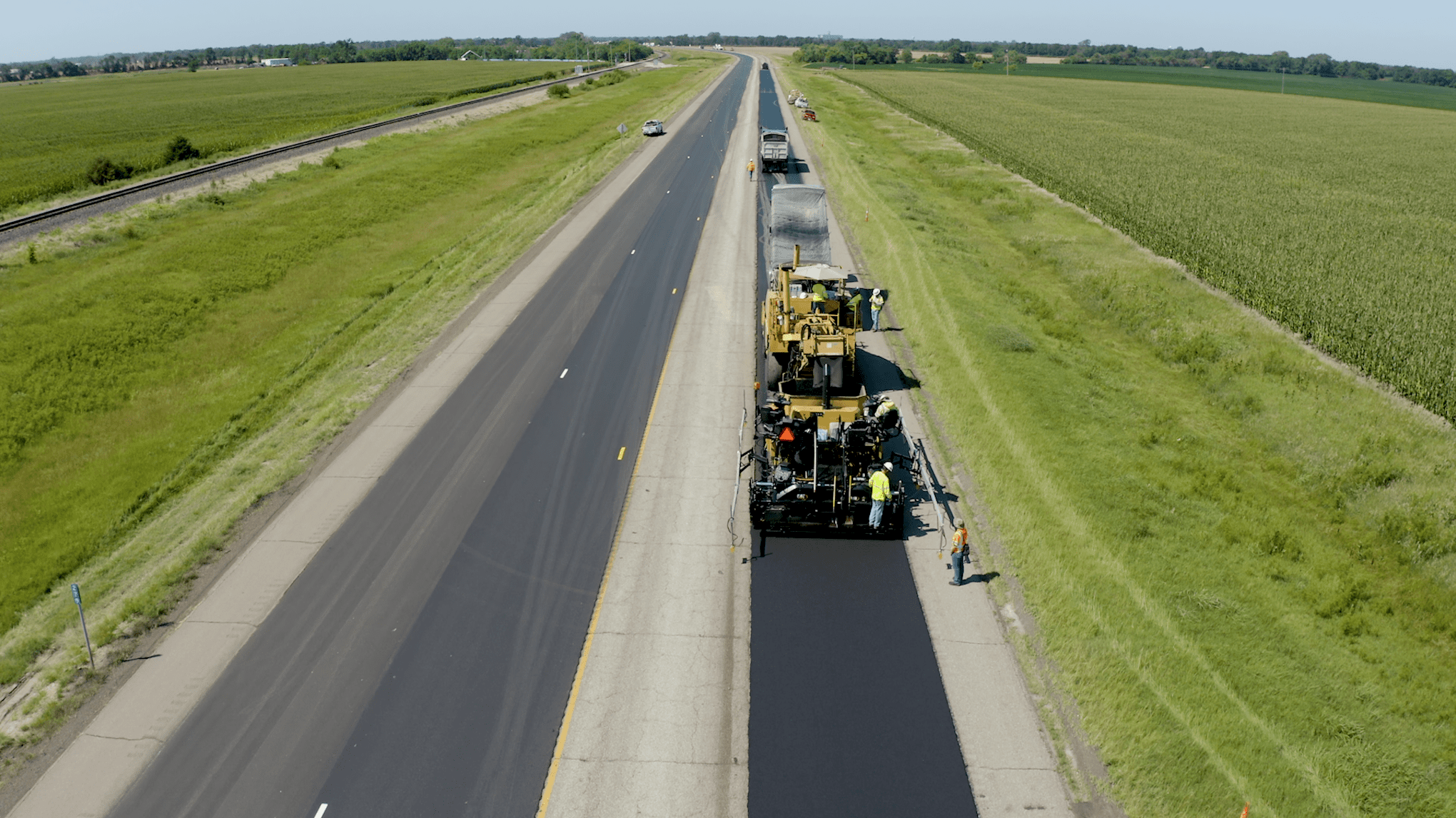

Our Construction Services team was brought on to provide construction inspection for the Kansas Department of Transportation (KDOT), overseeing the full scope of a 10-mile mill and overlay project. That includes chip seal shoulders to preserve the pavement edges, new rumble strips, and fresh pavement markings to keep drivers safe and the road efficient.

Inspection Process and Its Role in Quality Roadwork

In projects like this, inspection is often what makes the difference between a good road and a great one. It’s our job to make sure the work being done meets every requirement laid out by KDOT, from material quality to construction methods and field safety. We’re not just checking boxes, we’re making sure the road performs as designed and lasts as long as possible.

For asphalt paving work, that starts with the milling process. The existing pavement is milled down to create a clean, uniform surface for new asphalt to bond to. Our inspectors are on the ground, measuring the depth to ensure it’s neither too shallow nor too deep, which would affect the final pavement performance and material quantities.

We also check the milling equipment itself, specifically the condition of the milling teeth. Clean, sharp teeth result in a better surface texture and help the new asphalt adhere properly.

Next comes paving – as the paver follows the mill, our team checks that the right mix is coming out of the plant, that the depth and width match the design, and that the surface is free of imperfections like rock clusters, excess oil, or foreign material. If our inspectors spot something out of place, they flag it before it becomes a bigger issue.

Meanwhile, someone from our team is testing the density of the newly paved asphalt, making sure the material is compacted to specifications. Another team member is in the lab performing quality control tests to verify that the asphalt being laid is up to standard. Every step is tracked, measured, and documented. Every load is accounted for, and every inch of pavement gets the oversight it needs for an end product our clients are satisfied with.

The Power of a Complete Inspection Crew

There’s no such thing as a one-person inspection on a project of this size. It takes a full, coordinated team to cover the plant, mill, paver, lab, and density testing. Each role is essential to making sure the job is done right, safely, and on schedule. In our role as KDOT’s field representatives, we act as both their eyes and ears as well as a trusted partner to the contractor. We enforce the standards, but we also help solve problems, answer questions, and keep the work moving forward.

This is what our ‘No Problem’ approach truly means. It’s not just a slogan, it’s how we operate across every facet. We take full ownership of our part of the project and work proactively to make sure things don’t just get done, they get done right.

A Big Step for Wichita

With the US-50 project, we’re doing more than just inspecting newly paved road, we’re helping to lay the groundwork for safer travel, stronger infrastructure, and continued growth in the region. From boots-on-the-ground testing to contract administration, our team brings ‘No Problem’ experience, accountability, and attention to detail to every job.

This project also marks something bigger for our team: the expansion of our Construction Services into the Wichita Region. That means more opportunities to support KDOT, local municipalities, and regional clients throughout Kansas. It also means growing our inspection team and investing in the communities where we live, work, and play.

We’re proud of the work we’re doing here, and we’re just getting started.